by Keith Addison

Published in Asian Business, June 1982

|

Stories by Keith Addison |

| Tai Long Wan -- Tales from a vanishing village Introduction |

|

Tea money |

|

Back to basics |

|

Forbidden fruit |

|

A place where nothing happens |

|

No sugar |

|

Treasure in a bowl of porridge |

|

Hong Kong and Southeast Asia -- Journalist follows his nose |

| Nutrient Starved Soils Lead To Nutrient Starved People |

|

Cecil Rajendra A Third World Poet and His Works |

|

Leave the farmers alone Book review of "Indigenous Agricultural Revolution -- Ecology and Food Production in West Africa", by Paul Richards |

|

A timeless art Some of the finest objects ever made |

|

Health hazards dog progress in electronics sector The dark side of electronics -- what happens to the health of workers on the production line |

|

Mo man tai ('No problem') -- "Write whatever you like" -- a weekly column in Hong Kong Life magazine Oct. 1994-Jan. 1996 |

|

Swag bag Death of a Toyota |

|

Zebra Crossing -- On the wrong side of South Africa's racial divide.

|

|

Curriculum Vitae |

|

|

Hong Kong's high-flying electronics sector is not all glamour. There's a dark side as well -- what is happening to the health of workers on the production line. Keith Addison reports

| Health hazards dog progress in electronics sector also in UK 18 Jul 2003 Hi Keith On behalf of the TV electronics service engineers in the UK who have suffered for years with various illnesses I would like to thank you for all your research and efforts in showing us why and the unanswered questions. For years we have suffered strange rashes, colds lower back disorders and other symptoms, but this seems to have been common problems to fellow workers in Asia. In the last few years I have been the guinea pig in the medical world, Test proving I have Occupational Asthma, Dermatitis and Rynitis. and damage done to my lower spine and WRULDs and left disabled from just doing my job. Others are also been diagnosed with similar illnesses. TVs we worked on soldering in dark, cramped corners in customers' homes breathing in all sorts of fumes and chemicals. Never told the dangers until research after being made redundant from illness showed major health problems in the UK with service engineers over the years (40 years). Lifting large awkward TVs in/out of customers' homes have taken sometimes years to add to lower back conditions or immediate trauma. With lifting or moving without aids TVs 70-110kgs to repair. We as a group have found aids were out in 1979, and now a new lifting aid is on the market worldwide from Australia. All this information can be seen on these two websites: http://www.toddweb.co.uk http://www.liftingsystems.co.uk with other attachments and links. Please take a look. I have been asked to say thanks for your efforts and hope you could e-mail us a reply. We would also like to ask if we could put a link to your article so others can be warned, unfortunately to late for us. Your article has also helped us find that asbestos was in PCBs as one of our workmates has been diagnosed with mesothelioma from TVs at 49 years old. Once again thank you and hope this mail gets to you Robin Maudsley with other grateful TV personnel |

The first, by an independent economics research group in collaboration with a local community health centre, threatens to shatter the industry's reputation of providing its 95,000 workers with the cleanest, safest working environment in town.

The second, by the government sponsored Hong Kong Productivity Centre (HKPC), may precipitate a series of interventionist measures in contrast to the government's largely laissez-faire policies.

The two studies have a common cause: the unbalanced growth in manufacturing the HKPC hopes to redress and the angry denials which greeted the early findings of the health study are both symptoms of the quick-buck mentality on which local investment in the industry is largely based.

The industry's "clean" image was first questioned in July last year, when the Kwuntong Occupational Community Health Centre conducted a study backed by the Christian Industrial Committee and the United Christian Hospital and found evidence of widespread damage to eyesight and hearing, symptoms of stress and a variety of health problems caused by exposure to dangerous chemicals among electronics workers.

A press statement issued soon afterwards by the electronics group of the Federation of Hong Kong Industries angrily denied the existence of any health hazards. The electronics industry was the "cleanest and safest industry in the world", providing "one of the best, if not the best, working environments".

A press statement issued soon afterwards by the electronics group of the Federation of Hong Kong Industries angrily denied the existence of any health hazards. The electronics industry was the "cleanest and safest industry in the world", providing "one of the best, if not the best, working environments".The report was sensationalist, without foundation, vindictive, irresponsible, slanderous, unacceptable and highly damaging, the statement charged. It could frighten away workers and perhaps force some factories to relocate outside Hong Kong. It could also hamper government efforts to attract high-technology industries from overseas and to encourage diversification of Hong Kong's industries.

"We strongly urge the government to state its position on this type of detrimental activity," the statement said.

Taken aback by the fury of this response, the Kwuntong group, which had not yet finished its study, appealed to its research partner, Asia Monitor Resource Center, which entered the fray with a long and authoritative letter published in most of Hong Kong's leading newspapers, supporting the Kwuntong group's claims.

Serious hazards did exist, claimed Asia Monitor co-director Tom Gassert, citing the findings of work by the International Labour Organization and of the US government-sponsored Project on Health and Safety in Electronics (PHASE) being conducted in California's famous "Silicon Valley".

He slammed the local industrialists' lack of concern and the Labour Department's inadequate approach to the whole issue of chemical dangers in the workplace, as well as outdated government controls on dangerous chemicals.

Inadequate warning system

The next development in the controversy was the publication of the results of a survey of local electronics workers conducted by the Hong Kong and Kowloon Electronics Employees General Union, which had found that 70% of those examined were suffering from job-related health problems.

Despite all this smoke, the Labour Department's deputy chief factory inspector Yip Yuk-lun asserted in an interview that there is no fire: "We do not share the opinion of the Kwuntong group or the Asia Monitor Resource Center," he said. "The electronics industry, because of its cleanliness and good working environment, gives us very little trouble."

He waved away charges that workers were being poisoned by toxic fumes from molten solder and chemical fluxes: "I can assure you that all soldering baths have localized ventilation systems and exhausts."

He waved away charges that workers were being poisoned by toxic fumes from molten solder and chemical fluxes: "I can assure you that all soldering baths have localized ventilation systems and exhausts."

He admitted there was a problem with corrosive solvents and cleansing agents because workers were reluctant to wear the required protective gloves, but his inspectors informed workers of the dangers of the chemicals they were working with.

He also admitted his department was understaffed, with only 174 inspectors to visit 47,000 factories, but he insisted that his staff were in touch with most workers handling hazardous processes in the electronics industry's 1,115 factories.

Yet despite the Labour Department's publicity campaign, workers say the only warnings they have ever seen posted in their factories are no-smoking signs; they have never been told of hazards connected with their work.

Health researchers have seen factory girls (most electronics workers are female and young) removing nail polish with such deadly solvents as benzene and trichloroethylene. Benzene causes fatigue, loss of appetite, insomnia, nosebleeds and can cause leukemia, but it is still widely used by the industry in Hong Kong, despite warnings in literature printed by the government's Labour Department.

Health researchers have seen factory girls (most electronics workers are female and young) removing nail polish with such deadly solvents as benzene and trichloroethylene. Benzene causes fatigue, loss of appetite, insomnia, nosebleeds and can cause leukemia, but it is still widely used by the industry in Hong Kong, despite warnings in literature printed by the government's Labour Department.

The Labour Department rates trichloroethylene as slightly hazardous, but according to the findings of the PHASE group in California, exposure to its volatile fumes causes headaches, tremors, nausea, vomiting and insomnia and can lead to heart damage, kidney damage, liver disease, inner ear damage and brain damage, and there is evidence that it can cause miscarriages and birth defects.

It also causes skin damage and dermatitis and prolonged use can cause finger paralysis. It is in common use in Hong Kong electronics factories.

Other problems

Workers interviewed in several areas said their employers did not insist that they wear gloves, and one worker said he would not wear them even if ordered to because they slowed down the work: basic wages are low and it is only through production bonuses and overtime that most workers can make ends meet. The centre has assembled what it claims is an unrivalled collection of authenticated information on chemical hazards from world-wide sources and will use this information in conjunction with the Kwuntong group's findings to produce an easy and thorough reference for workers to find out what chemicals they are using, what hazards they represent, and what can be done about it in terms of protection and prevention as well as the highly restrictive labour laws of many East Asian countries. "Japan, Taiwan, South Korea and even Singapore are all concentrating on high technology industrial electronics now, but in Hong Kong we are seeing the reverse trend, because there is no mechanism here to guide industry in that direction," Chan said.

In any event, gloves are not the answer. Recent US government tests showed that most brands of gloves allowed seepage within minutes. The Labour Department recommends the additional use of a barrier cream, but creams are even rarer than gloves.

Yip's assurance that all solder baths have localized exhausts is not true. For instance, the solder baths and acid baths used in the tin plating process at Semiconductor Devices in Aberdeen have no localized exhausts. Neither is the tin plating room air-conditioned: instead there are two extractor fans, one at each end of the room, and two other fans. That is neither adequate nor particularly unusual.

The point is that not all soldering work involves solder baths. Many workers are employed on touch-up work after the components have passed through the bath, using hand-held soldering irons and wire solder, and the fumes from solder and flux come straight up into their faces. None of these workers is adequately protected.

All the soldering work at Applied Electronics, also in Aberdeen, is done by hand, with no local exhausts and poor ventilation; the fumes are visible and the smell suffocating.

At the Contec factory in Kwuntong, one of the best equipped local electronics factories, the tin plating process is fully automated and properly ventilated, but long lines of touch-up workers using hand-held soldering irons are not protected at all.

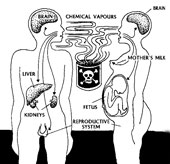

Solders contain tin, lead, antimony, arsenic, cadmium, silver and zinc. Exposure to the oxidized fumes of these metals can cause anaemia, digestive problems, nerve damage, lung problems, heart trouble, reproductive problems and increased cancer risks.

Solders contain tin, lead, antimony, arsenic, cadmium, silver and zinc. Exposure to the oxidized fumes of these metals can cause anaemia, digestive problems, nerve damage, lung problems, heart trouble, reproductive problems and increased cancer risks.

Fumes from fluxes cause a range of ailments affecting the skin, eyes, nose and throat, chest, stomach, kidneys, liver, nervous system, heart and reproductive system, and increase cancer risks. Similarly serious problems are associated with chemicals found in the epoxy resins, hardeners and solvents used to make printed circuit boards.

There are other problems, not associated with chemicals. The tremendous pace set on the production lines produces stress symptoms; workers spending long hours, often illegally long, assembling micro-components under powerful microscopes suffer eye strain and permanent vision impairment; high noise levels exacerbate hearing problems caused by chemical exposure.

Testing for vision and hearing impairment is simple, and both the Kwuntong group and the union did this in their studies, but determining the effects of chemical exposure is more difficult, often entailing complicated laboratory analysis of blood samples and tests which cannot be done in Hong Kong.

Local electronics workers have a high rate of mobility between different jobs in the same factory and between factories, which makes it extremely difficult to trace the exact causes of their health problems.

Different jobs mean exposure to different chemicals at different intensities for different periods of time, making the task impossibly complex, and virtually nothing is known of the synergistic effects of different chemicals combining with each other in the body.

Of those examined by the Kwuntong group, 56% had vision deficiencies and 30% had hearing problems. Of those surveyed, 30% had hearing problems and 73% complained of noise in the workplace. Half of those doing soldering work had no local exhaust systems and 31% of workers doing hand soldering had eye injuries from sparks and splashes, while most complained of irritation from fumes. Nearly half were in daily contact with chemicals.

The most common problems found were eye strain, headaches, drowsiness, insomnia, poor vision, pains in hands and feet, dizziness and backache. About 80% thought their health problems were associated with their work and about 10% had been assured by their doctors that this was so.

"Health Hazards in Electronics -- A Handbook", by Thomas Gassert, 1985, English, 411pp (ed. Keith Addison) -- quick-reference, action-oriented, thorough information on health hazards faced by workers.

Available from Asia Monitor Resource Center

http://www.amrc.org.hk/resboks.htm

"Most of the problems could be expected," said a doctor who was associated with the study. "What we found corresponds well with findings in western countries." The union, which had 500 of its members medically examined, produced similar results.

The Asia Monitor Resource Center is currently incorporating the Kwuntong case study into a general primer on chemical hazards in the electronics industry for use by workers and labour organizations throughout East Asia, to be published later this year in English, Chinese and all the ASEAN languages.

The project is going ahead in spite of the controversial expulsion from Hong Kong in March of American lawyer Christine Vertucci, who had headed the project.

Mounting awareness

The project has already attracted interest from local medical people and the universities and from international bodies such as the World Health Organization (WHO) and the International Labour Organization (ILO). It is very much in line with a recent appeal for co-operation by governments, employers, workers and specialized groups in a joint International Program on Chemical Safety sponsored by the ILO, WHO and the UN Environment Program (UNEP).

With some 50,000 chemicals now in daily use, and between 500 and 1,000 new chemicals added each year, often before their toxicity has been assessed, the problem of analysing risks of health hazards and seeking ways to prevent them had become enormous, the ILO said. The proliferation of new chemicals had created a serious research gap, while industrial experience and epidemiological studies continued to reveal more areas of danger.

In Hong Kong, a growing worker awareness of the problem will ensure that it will not simply go away, no matter how much local industrialists and perhaps the government might wish it to do so. It is a serious problem and sooner or later it will have to be dealt with.

"The difficulty lies in the fact that Hong Kong entrepreneurs don't like putting capital investment into these areas," said Dr Edmond Chan, who is in charge of the Hong Kong Productivity Centre's study of the electronics industry.

"They want a quick return on their money. Our survey of the industry has revealed that the average break-even period a local manufacturer requires is only 2.9 years.

"It is not possible to isolate one problem like this: you have to look at the whole thing. For instance, if you look at the average company, the reason they set up a production line is that they already have an overseas order on which they know they can make a profit.

"So they set up a production line with the minimum of capital investment, and if they do not receive a second order, they simply close down the line. If they had their own marketing outlets and expertise instead of relying on orders from trading houses, that would not happen, and they would be able to sustain a longer-term type of production which they would be more willing to invest capital in."

Rising labour and land costs have made it increasingly difficult for foreign suppliers to continue manufacturing components in Hong Kong, and this has been a major factor in the transfer of investment from foreign to local interests, accompanied by a rapid shift in product emphasis: between 1976 and 1980, components and parts fell from 40% of total export value to slightly above 20%, while consumer electronics -- quartz watches, TV games, radios, radio cassettes, Walkman-type stereos -- grew from 50% to over 70%.

In terms of quick profits, that is a favourable trend as the market for consumer electronics is big and Hong Kong's highly flexible industries are well equipped to deal with it.

But it is also an unhealthy trend, for the consumer market is not stable: demand for fashion products follows economic trends much faster than that for components or industrial electronics, and there is also the problem of protectionism. The heavy emphasis on consumer products is endangering the electronics industry's ability to provide a stable substitute in the economy for the ailing textiles industry.First steps to solutions

"Development of microprocessors and products using microcomputers for control of manufacturing processes is exactly the area our industrialists don't want to go into, because investment is much higher and much longer-term. But they will have to be persuaded to do so.'

There are other difficulties: the necessary support industries -- metal and metal finishing, precision engineering, computer peripherals manufacturing -- are almost non-existent.

With this in mind, the HKPC organized the Electronics Show '82 early in March, to help local manufacturers find appropriate ancillary machinery, followed by the Machine Tools Exhibition '82, which aimed to help upgrade the local metal working industry.

There is also a serious lack of local expertise in microcomputer technology, but another project under Chan's supervision is designed to begin to counter this lack.

"We have started a microprocessor application laboratory, the first application oriented research laboratory to be operated by the government," he said.

"The purpose is to build up local expertise in upgrading manufacturing technology, both in terms of process and product design. It is still small, but it is a beginning. We have a staff of 15, which will soon be increased to 20. We are designing products using microprocessors and systems using microcomputers for process control to upgrade manufacturing techniques, for use by Hong Kong industries. We will also provide a consultancy service.'

Another important area the study team is investigating is the possibility of promoting inter-company collaboration in the electronics industry.

"This is another of the local industry's weaknesses," Chan said. "Local manufacturers are very competitive, but they often end up cutting each other's throats to the detriment of the industry as a whole. We have to find ways of getting them together, though it will be difficult.'

Longer-term investment could obviously be facilitated if small companies were to share the costs of product development and overseas marketing operations. "We plan to intervene a little bit here and there, so that the companies will be able to develop further on their own," Chan said.

"The government is very reluctant to change its laissez-faire policies, but they will probably be able to swallow the sort of thing we are planning. They do know that if industry is going to diversify, they have to intervene; there is no other way."

It is a crucial problem, for unless the electronics industry develops high-technology expertise other industries will not have the means to upgrade their manufacturing processes to stay competitive in the international market.

A new industrial revolution centred on the electronics sector could provide some of the answers to the industry's occupational health problems. A work force acknowledged as a valuable resource -- instead of mere machine fodder -- is obviously worth conserving over the long term.

-- Asian Business, June 1982

(Illustrations from "Health Hazards in Electronics -- A Handbook")